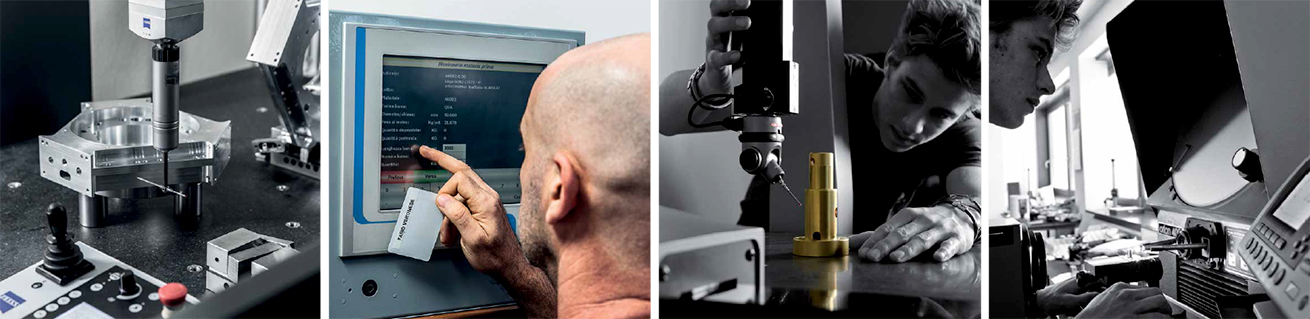

FROM COMPLYING WITH THE PRODUCTION PROTOCOL TO VERIFYING DIMENSIONS OF

MANAGMENT

+ Sophisticated planning software drives the production system according to a precise protocol since estimate issue.

CAD-CAM SYSTEMS

+The latest CAD-CAM systems provide product models from which we obtain specific lead times, costs and data to set and equip machines correctly.

BADGE

+ Each operator has a badge containing information about project status - from collecting the material from the warehouse to recording set-up and phase times. This provides us with real-time machine loading views.

METROLOGY

+ Products undergo dimensional verification, geometry inspection and hardness testing in our metrology and measurement facility.

INDUSTRY/4.0

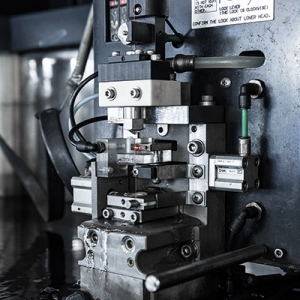

A DIGITAL REVOLUTION IS ALREADY TAKING PLACE

Real-time production monitoring, sharing of data and methodical analysis of results prompt us to improve our performances constantly.

IMAGE INFO

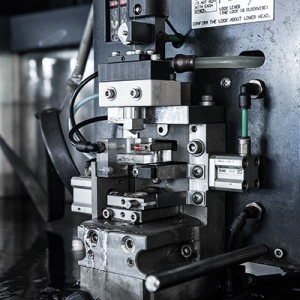

All our machines are connected. Custom-made software provides real-time information about factory automation.

Real-time production monitoring, sharing of data and methodical analysis of results prompt us to improve our performances constantly.

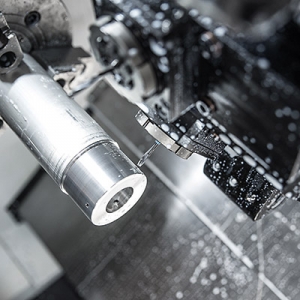

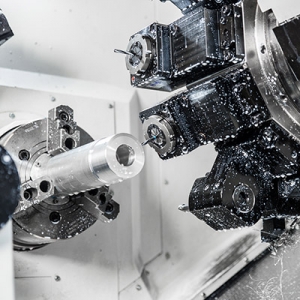

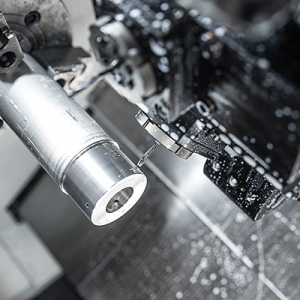

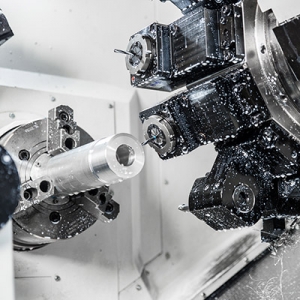

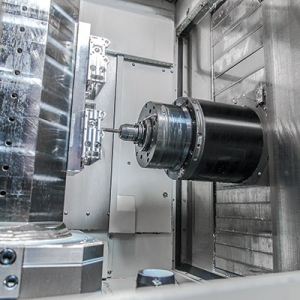

WORK IN PROGRESS/

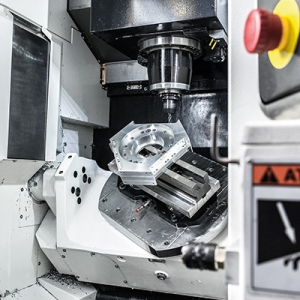

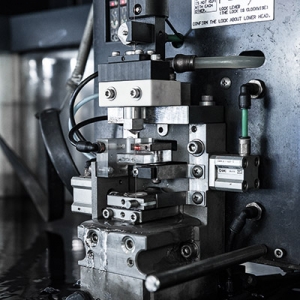

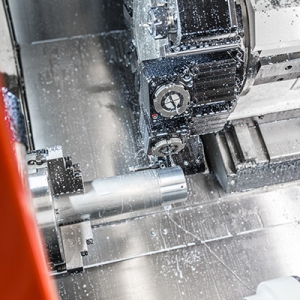

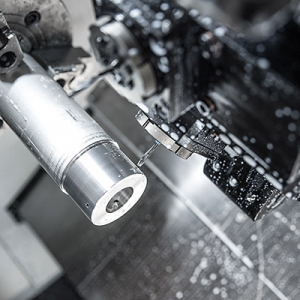

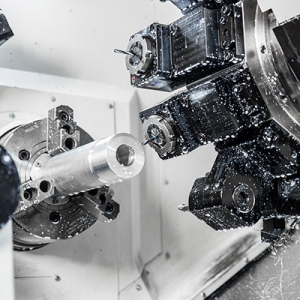

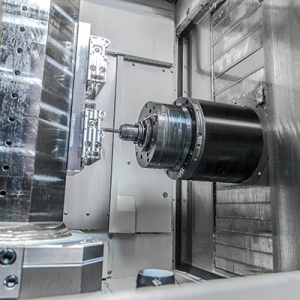

THE MACHINES AND TOOLS WE USE

TO PROVIDE EXCELLENCE ARE CONSTANTLY UPGRADED

WORK IN PROGRESS/

THE MACHINES AND TOOLS WE USE

TO PROVIDE EXCELLENCE ARE CONSTANTLY UPGRADED

+ REPARTO TORNITURA A CONTROLLO NUMERICO

+ REPARTO FRESATURA A CONTROLLO NUMERICO

+ LAVORAZIONI COMPLEMENTARI

+ SALA METROLOGICA E DI CONTROLLO

+ UFFICIO TECNICO DI PROGRAMMAZIONE

ELLE EMME S.R.L.

MECCANICA DI PRECISIONE

P.I. IT02663530281

capitale sociale € 100.000,00 interamente versato

VIa 11 Settembre, 30

Z.A. Loc. Ronchi

Villafranca Padovana - PD

» Privacy Policy

» Copyright 2018

AREA RISERVATA

» accedi

PROGETTO GRAFICO E FOTO:

Ruzza Marco - Curtarolo - PD

www.marcoruzza.it